RECIPES FOR YOUR

BUSINESS

-Slaughter & deboning >>

BUSINESS

-Slaughter & deboning >>

Engineering and construction sheep and cattle slaughterhouses, deboning rooms, skin process, white and red offal treatment, wastewater treatment plants

Recipes for your

business

-sausages & patties>>

business

-sausages & patties>>

Engineering and construction of meat processing factories, central kitchen and butcher shops with full turnkey European equipment supply and service

Recipes for your

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

RECIPES FOR YOUR

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

RECIPES FOR YOUR BUSINESS

-Water & drinks>>

-Water & drinks>>

Engineering, supply of ambient and carbonated filling plants

Pneumatic installation

Pneumatic installations - quick assembly system

Plug-in installations in the system are characterized by a very simple assembly, which saves about 40% of the investment value, due to the possibility of self-execution.

Strengths:

- simple and quick assembly (no gluing or welding)

- ideal for compressed air

- top quality products

- quick disconnection and disassembly

- no additional seals

- very good flow properties

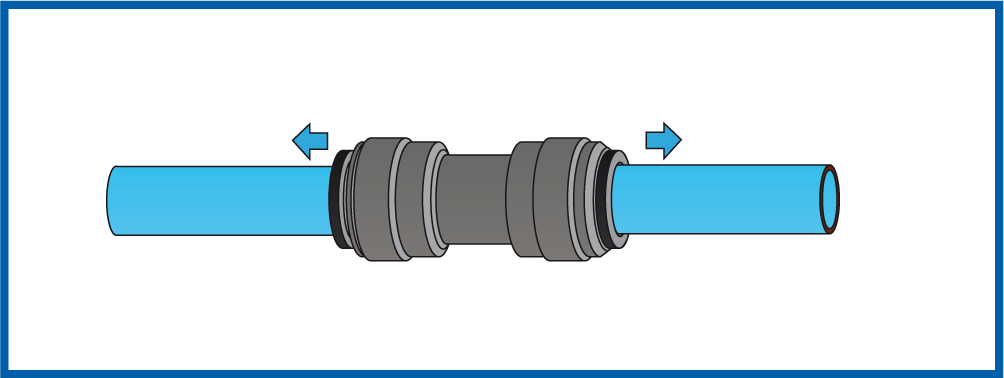

Assembly / disassembly connection diameter 15 mm - 22 mm

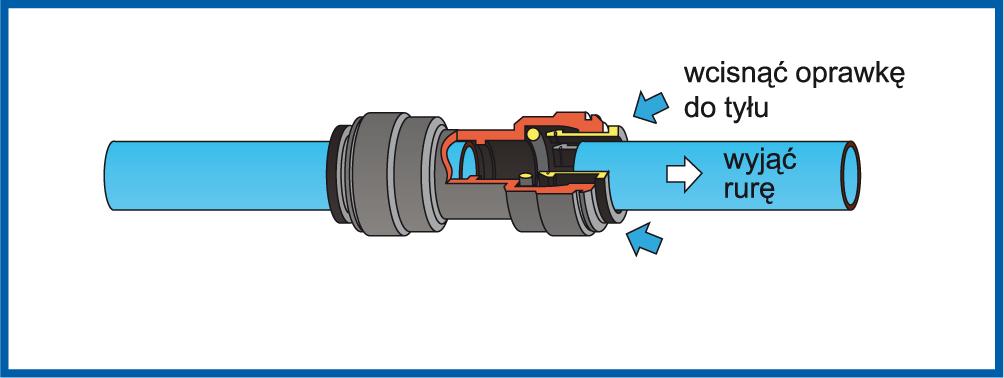

1. Cut the pipe at right angles, remove burrs. Check that the pipe has no sharp edges, longitudinal scratches and no other damage.

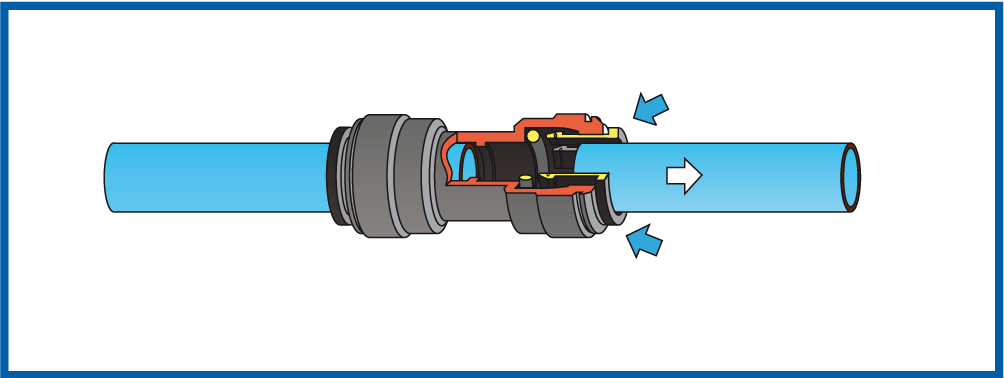

2. The coupler grips the pipe before sealing. Push the pipe all the way in.

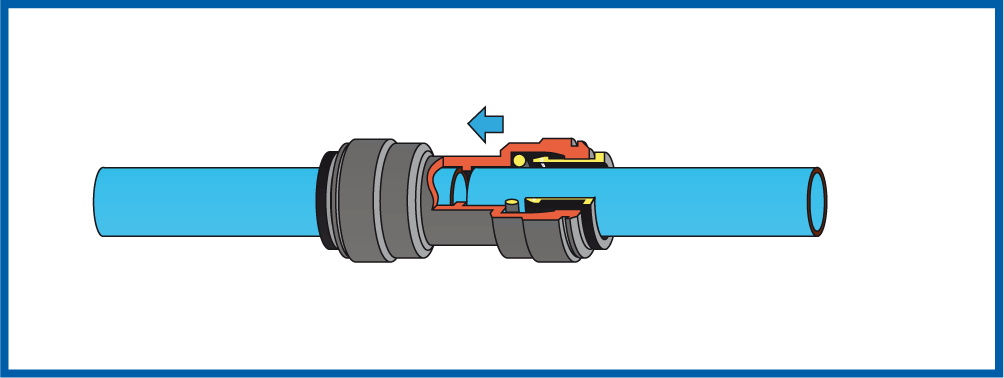

3. Push the pipe all the way in. The lampholder has stainless steel teeth and fixes the tube in the fitting. The sealing ring creates a perfectly tight connection.

4. Check the connection by stretching the pipe. Make sure the pipe is securely seated. This can be seen by pulling the pipe in opposite directions

Disconnecting the connection

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production