RECIPES FOR YOUR

BUSINESS

-Slaughter & deboning >>

BUSINESS

-Slaughter & deboning >>

Engineering and construction sheep and cattle slaughterhouses, deboning rooms, skin process, white and red offal treatment, wastewater treatment plants

Recipes for your

business

-sausages & patties>>

business

-sausages & patties>>

Engineering and construction of meat processing factories, central kitchen and butcher shops with full turnkey European equipment supply and service

Recipes for your

business

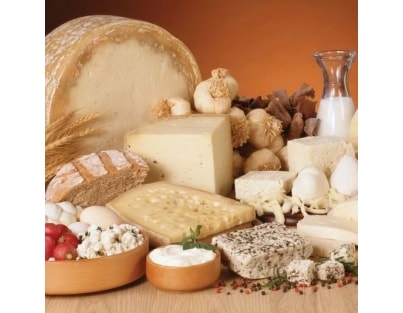

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

RECIPES FOR YOUR

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

RECIPES FOR YOUR BUSINESS

-Water & drinks>>

-Water & drinks>>

Engineering, supply of ambient and carbonated filling plants

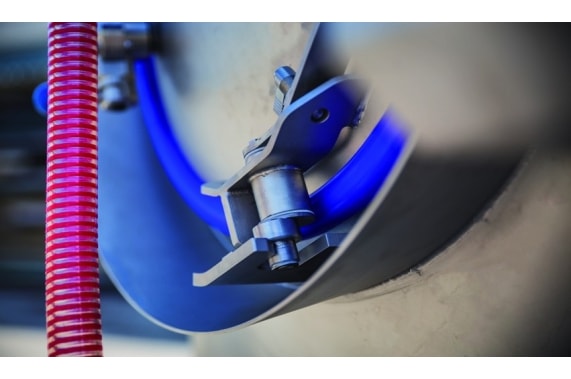

Horizontal vacuum massaging tumblers ECO

Horizontal vacuum massaging tumblers ECO

| GENERAL TECHNICAL DATA | |

| Drum volume | 650-12000 lt |

| Massaging capacity | 275-5400 kg |

| Rotational speed (continuously adjustable) | 0.5-16 rpm |

| Cooling aggregate version "COOL" | 2,2-7kW |

| Vacuum pump | 0,55-5.5kW |

| Drive motor | 0,75-15kW |

| Installed power COOL |

2,3-20.5kW 4,5-27.9kW |

| Weight | 700-3900 kg |

Vacuum tumblers in a compact design for processing almost all types of bone and boneless meat raw materials. A large selection of drums of various sizes, the possibility of execution with and without a cooling system allow the use of ECO series massagers both in medium and large meat processing enterprises.

Cooling

Optionally with stand-alone refrigeration unit, heat exchanger or direct connection to the plant's existing glycol refrigeration system

Version "DM"

- temperature control sensor inside the drum

- drum cooling jacket

- direct connection to the plant's existing glycol refrigeration system (including control valve)

Version "COOL"

- temperature control sensor inside the drum

- drum cooling jacket

- external refrigeration unit

- product cooling down to approx. -2°C

User-friendly control panel with touch display "ISC-B05" Unitronic / IP 65 storage of 99 freely programmable recipes, manual control mode and automatic program execution mode.

Gentle or intensive massaging

- high-performance chain drive with infinitely variable speed control of the drum

- one curved welded paddle for an optimal massaging process

- easy loading by turning the drum to the left, convenient unloading by turning the drum to the right

Advantages

- the water separator is located at eye level

- liquid accumulation is excluded due to inclined surfaces

- easy cleaning, visually accessible vacuum hose • location of electrics, drive and other components at the rear of the massager • minimal operating costs and low wear

| Options | Description |

| Light in the bowl | For visual control of the process |

| Weighting sensors | For checking the weight of the product |

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production