BUSINESS

-Slaughter & deboning >>

business

-sausages & patties>>

business

-milk & cheese >>

Engineering, supply and installation of milk processing and cheese production plants

BUSINESS

-Flour & pasta>>

Engineering and construction milling and pasta processing plants

-Water & drinks>>

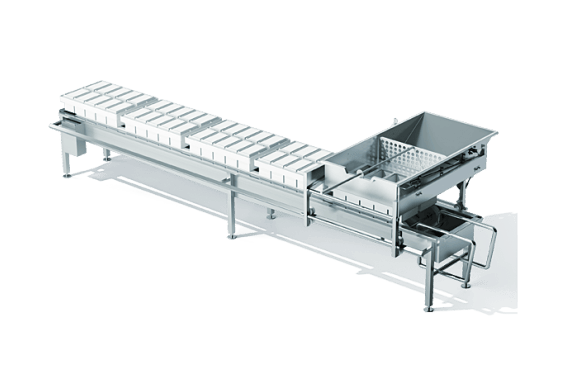

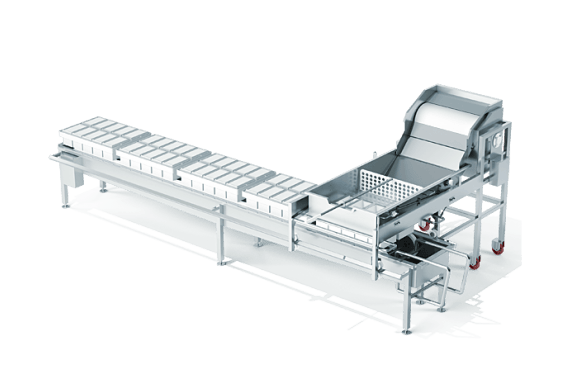

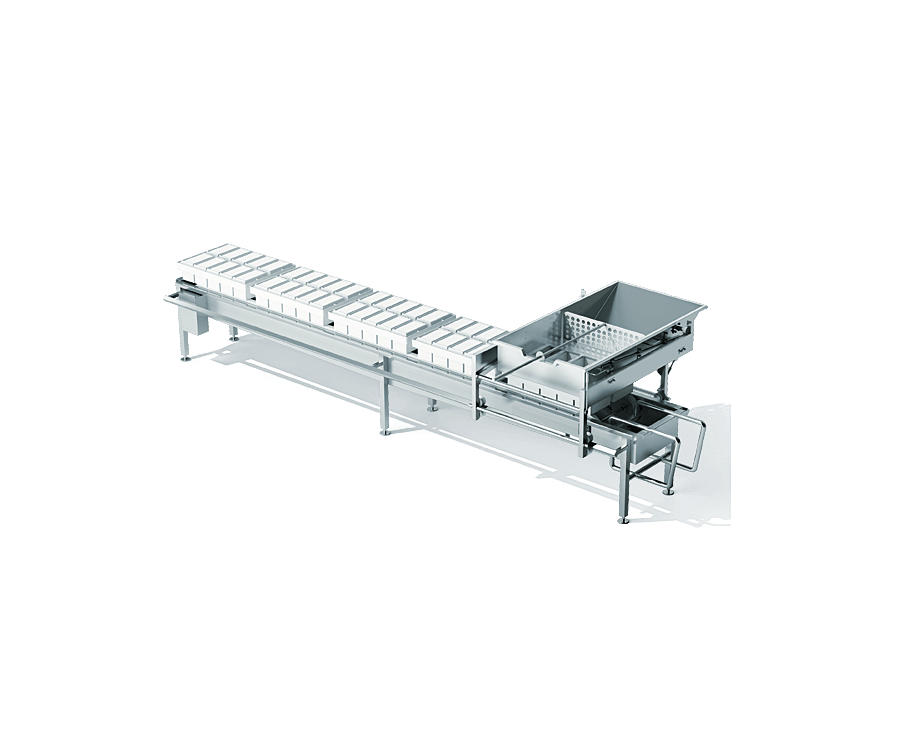

A module for the filling of moulds and block moulds with an integrated conveyor belt | DONI®Moulder

A module for the filling of moulds and block moulds with an integrated conveyor belt | DONI®Moulder

| GENERAL TECHNICAL DATA | |

| Power (kW): | 0,55 /without a conveyor belt/ |

| Length (mm): | DONI®Moulder ND - max 18 000 /with a conveyor belt/, DONI®Moulder YD - max 18 000 /with a conveyor belt/ |

| Width (mm): | DONI®Moulder ND - 1 900, DONI®Moulder YD - 2 500 |

| Height (mm): | DONI®Moulder ND - 1 100, DONI®Moulder YD - 1 700 |

The module is moved manually along guide bars on the conveyor belt. It is positioned in front of the DONI®Open U Vat for the discharging of the curd-whey mixture and for the moulding into block moulds which are placed onto the conveyor belt one by one. The filling is performed manually with a paddle. The cycle duration is no longer than a minute. Two workers are required to operate the module. DONI®Moulder has a system that regulates the filling height in order to achieve finished products with the same weight. DONIDO® offers two мodels of the module:

- DONI®Moulder ND without a draining drum for products with high dry content or with partially drained whey;

- DONI®Moulder YD with a draining drum for partial drainage of the whey.

The conveyor belt length is determined by the characteristics of the production site. DONIDO® recommends this module when the block moulds have extensions and additional time is required for the settling of the curd and for the releasing of the extensions before stacking. The module is cleaned locally.

Abattoir for cattle and sheep

Short | long | special shape pasta lines production

Lines for hard and soft cheese production

Steam generators and watertreatment

Burgers | nuggets | skewers | meatballs

Delicatessen production

Beverage industry plant engineering

Packaging equipment

Stew canning meat, sauces and vegetable lines production